RO Water Plant Spares

Micron Filter Cartridges

Wound Polypropylene Cartridges

Available in 10″, 20″, 30″ and 40″ lengths

Available in 10″, 20″, 30″ and 40″ lengths-

Standard Diameters – 63 mm (Slim type) & 114 mm (Jumbo type)

Standard Diameters – 63 mm (Slim type) & 114 mm (Jumbo type)  Micron ratings available from 0.5 to 100 micron

Micron ratings available from 0.5 to 100 micron-

Low Pressure Drop

Low Pressure Drop -

High Dirt Holding Capacity

High Dirt Holding Capacity -

Made of FDA Grade Polypropylene yarn with PP core

Made of FDA Grade Polypropylene yarn with PP core  No Fibre migration into the filtered product

No Fibre migration into the filtered product-

Highly Stable media structure

Highly Stable media structure -

Wound Glass Fiber with SS or TIN core also available

Wound Glass Fiber with SS or TIN core also available

Melt Blown Polypropylene Cartridges

-

Available in 10″, 20″, 30″ and 40″ lengths

Available in 10″, 20″, 30″ and 40″ lengths -

Standard Diameters – 63 mm (Slim type) & 114 mm (Jumbo type)

Standard Diameters – 63 mm (Slim type) & 114 mm (Jumbo type) -

Micron ratings available from 0.5 to 100 micron

Micron ratings available from 0.5 to 100 micron -

Low Pressure Drop

Low Pressure Drop -

High Dirt Holding Capacity

High Dirt Holding Capacity -

Made of FDA Grade Polypropylene

Made of FDA Grade Polypropylene -

Single piece construction

Single piece construction -

Different cartridge weights available for domestic & industrial applications as per requirement

Different cartridge weights available for domestic & industrial applications as per requirement -

Customization is possible in terms of length if required

Customization is possible in terms of length if required

Pleated Polypropylene Cartridges

-

All Polypropylene construction

All Polypropylene construction -

Available in 10″, 20″, 30″ and 40″

Available in 10″, 20″, 30″ and 40″ -

Standard Micron ratings – 0.1, 0.45, 1, 5 micron

Standard Micron ratings – 0.1, 0.45, 1, 5 micron -

Thermally welded construction

Thermally welded construction -

FDA Approved raw material

FDA Approved raw material -

Available in both DOE and Code 7 type construction

Available in both DOE and Code 7 type construction

FRP Vessels

-

Standard Sizes Available – 844, 1054, 1252, 1354, 1465, 1865, 2162, 2472, 3072, 3672, 4272, 4872

Standard Sizes Available – 844, 1054, 1252, 1354, 1465, 1865, 2162, 2472, 3072, 3672, 4272, 4872 -

Maximum Operating Pressure < 150 psi

Maximum Operating Pressure < 150 psi -

Vessels are “burst tested” at 4 times the rated pressure

Vessels are “burst tested” at 4 times the rated pressure -

Distribution Systems available

Distribution Systems available -

FRP Liner / PE Liner available

FRP Liner / PE Liner available -

Smooth Internal Finish

Smooth Internal Finish -

2.5″ , 4″ and 6″ flanged openings available

2.5″ , 4″ and 6″ flanged openings available

R.O. Membranes

-

Brackish Water, Sea Water, UF, NF, Low Fouling Membranes, Low Energy membranes available

Brackish Water, Sea Water, UF, NF, Low Fouling Membranes, Low Energy membranes available -

Hydranautics, Filmtec, CSM etc

Hydranautics, Filmtec, CSM etc -

Standard Sizes of 4040 & 8040

Standard Sizes of 4040 & 8040

R.O. Pressure Vessels

-

8 inch, 4 inch and 2.5 inch diameters

8 inch, 4 inch and 2.5 inch diameters -

End port, side port and multi-port options

End port, side port and multi-port options -

All pressure ratings from 250 psi to 1200 psi

All pressure ratings from 250 psi to 1200 psi -

Smooth internal finish to hold all membranes

Smooth internal finish to hold all membranes -

Ability to accommodate 40 inch long RO/NF/UF spiral Wound membrane elements

Ability to accommodate 40 inch long RO/NF/UF spiral Wound membrane elements -

Vessels are designed to a safety factor of 6 times the design pressure

Vessels are designed to a safety factor of 6 times the design pressure -

Each vessel tested for 1.5 times the working pressure before despatch

Each vessel tested for 1.5 times the working pressure before despatch -

Vessel sizes available for up to 6 membranes per vessel

Vessel sizes available for up to 6 membranes per vessel

R.O. Skids

Types

-

Vertical Mounting (upto 1000lph-4″ membrane housing)

Vertical Mounting (upto 1000lph-4″ membrane housing) -

Horizontal Mounting Skids (upto 25,000 lph) . Mounting here is for RO membrane housing only.

Horizontal Mounting Skids (upto 25,000 lph) . Mounting here is for RO membrane housing only.

MOC

-

MS Powder coated skids

MS Powder coated skids -

Stainless Steel 304 Skids

Stainless Steel 304 Skids

Panel Types

-

Logic Controlled Automatic & Semi-Automatic Electrical panels.

Logic Controlled Automatic & Semi-Automatic Electrical panels. -

PLC based automatic control panels.

PLC based automatic control panels. -

Manual control Panels.

Manual control Panels.

Specification:

Every RO Skid shall be designed to accommodate the following components.

-

Cartridge Filter Housing

Cartridge Filter Housing -

Pressure Gauges

Pressure Gauges  Flow Meters

Flow Meters-

Control Panels

Control Panels -

Pressure Switches

Pressure Switches  High Pressure Pumps

High Pressure Pumps-

UV System*

UV System* -

Membrane housings with membranes

Membrane housings with membranes -

Pipeline

Pipeline -

Control indicators

Control indicators

All RO skids are designed technically for easy maintenance and easy installation.

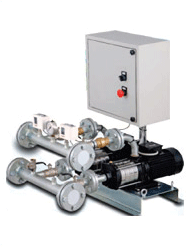

Pumps

Authorised Dealer for CRI PUMPS

-

High Pressure Vertical Multi Stage Pumps

High Pressure Vertical Multi Stage Pumps -

Centrifugal Mono Block Pumps

Centrifugal Mono Block Pumps -

Horizontal Multistage Booster Pumps

Horizontal Multistage Booster Pumps -

Sewage Pumps

Sewage Pumps -

Jet Pumps

Jet Pumps -

Regenerative Mono Block Pumps

Regenerative Mono Block Pumps -

Open well Submersible Pumps

Open well Submersible Pumps

Flow Meters

-

Panel Type & Online Type designs available

Panel Type & Online Type designs available -

Made of Acrylic Body

Made of Acrylic Body -

SS304 Float and SS316 Guide Rods with PP end connections

SS304 Float and SS316 Guide Rods with PP end connections -

Wide range available from 400 LPH to 50,000 LPH

Wide range available from 400 LPH to 50,000 LPH  Accuracy of +/- 2.5%

Accuracy of +/- 2.5%

Pressure Gauges

-

SS Body or MS Body available

SS Body or MS Body available -

Liquid Filled and normal pressure gauges as required

Liquid Filled and normal pressure gauges as required -

Bottom and back connections

Bottom and back connections -

2″, 2.5″ and 3.5″ dial sizes

2″, 2.5″ and 3.5″ dial sizes -

Normal ranges available are 0-100 psi and 0-300 psi

Normal ranges available are 0-100 psi and 0-300 psi -

Higher ranges available on request

Higher ranges available on request -

Accuracy of +/- 2.5%

Accuracy of +/- 2.5%

Butterfly Valves

-

Sizes Available:DN 50 to DN 600

Sizes Available:DN 50 to DN 600 -

Pressure Rating: 10 bar / 16 bar

Pressure Rating: 10 bar / 16 bar -

Body: CI/Ductile Iron/ WCB/ CF8 – Single piece or Short Wafer Type or Wafer Lugged construction

Body: CI/Ductile Iron/ WCB/ CF8 – Single piece or Short Wafer Type or Wafer Lugged construction  Disc: SG Iron / CF8 / CF8M

Disc: SG Iron / CF8 / CF8M-

Seal: EPDM / Nitrile – Integrally bonded replaceable seal

Seal: EPDM / Nitrile – Integrally bonded replaceable seal -

Shaft: AISI 310 / AISI 410

Shaft: AISI 310 / AISI 410 -

Operating Temperature: -40˚C to 180˚ C

Operating Temperature: -40˚C to 180˚ C -

Operation – Hand Lever / Worm Gear / Pneumatic Type

Operation – Hand Lever / Worm Gear / Pneumatic Type

Multi-Port Valves

-

Manual MPV

Manual MPV -

Semi-Automatic MPV

Semi-Automatic MPV -

Automatic MPV

Automatic MPV -

Sizes available – 20NB, 25NB, 40NB & 65 NB

Sizes available – 20NB, 25NB, 40NB & 65 NB -

Top Mount & Side Mount Valves available as per requirement

Top Mount & Side Mount Valves available as per requirement -

Valves for Filter, Softener & DM Applications

Valves for Filter, Softener & DM Applications -

Distribution Systems, Ejectors, Brine Detectors

Distribution Systems, Ejectors, Brine Detectors -

RO Panel

RO Panel -

Fully Automatic RO Controllers

Fully Automatic RO Controllers -

Remote Monitoring Automatic RO Controllers

Remote Monitoring Automatic RO Controllers

Housings For Cartridge Filters

-

PP Housings & SS Housings Available

PP Housings & SS Housings Available -

PP Housings available in 10″ & 20″ in both Slim & Jumbo type

PP Housings available in 10″ & 20″ in both Slim & Jumbo type -

SS Housings available in Single or Multi Cartridge arrangement as required for all sizes of cartridges

SS Housings available in Single or Multi Cartridge arrangement as required for all sizes of cartridges

TDS/Conductivity Meters

-

Handheld & Panel Mounted Instruments Available

Handheld & Panel Mounted Instruments Available -

Handheld TDS Meter

Handheld TDS Meter

- Range: 0-10,000 ppm

- Automatic Temperature Compensation

- Portable

- Accuracy of +/- 2.5%

Panel Mounted TDS Meter / Conductivity Meter

Panel Mounted TDS Meter / Conductivity Meter

- Range for TDS measurement: 0-20, 0-200, 0-2000 ppm

- Range for conductivity measurement: 0-20, 0-200, 0-2000 micro siemens

- Range switch over & constant check points can be freely set & adjusted

- Unique signal collecting technology & thick film circuit for high accuracy

- Accuracy of +/- 1.5%

- Automatic temperature compensation

Sensors, Switches & Transmitters

Flow Sensors – In Line Turbine Type

-

¾ inch/20 NB Flow Sensor Max Flow-1000 lph

¾ inch/20 NB Flow Sensor Max Flow-1000 lph -

1 inch/25 NB Flow Sensor Max Flow-6000 lph

1 inch/25 NB Flow Sensor Max Flow-6000 lph -

2 inch/50 NB Flow Sensor Max Flow-25000 lph

2 inch/50 NB Flow Sensor Max Flow-25000 lph -

Insertion Type Flow Sensor, In Line Paddlewheel Type Pulse Flow Sensor

Insertion Type Flow Sensor, In Line Paddlewheel Type Pulse Flow Sensor

Switches

-

Dosing Switch – Positive Displacement Dosing Flow Sensors

Dosing Switch – Positive Displacement Dosing Flow Sensors -

Brine Switch – Level Switch to Detect Brine

Brine Switch – Level Switch to Detect Brine -

Floaty – Level Switches for Auto MPV based Level Control, Wire – Common/NO/NC Potential Free Contact

Floaty – Level Switches for Auto MPV based Level Control, Wire – Common/NO/NC Potential Free Contact

Transmitter

-

4-20mA, 4-wire Conductivity Transmitter

4-20mA, 4-wire Conductivity Transmitter -

4-20mA, 4 wire pH Transmitter

4-20mA, 4 wire pH Transmitter -

4-20mA, +/- 1000mV, 4 wire ORP Transmitter

4-20mA, +/- 1000mV, 4 wire ORP Transmitter

Control & Monitoring Systems

Local Control Unit (LCU)

-

2 line display of 6 instruments & plant status

2 line display of 6 instruments & plant status -

Transmits all plant data & status at desired frequency via SMS

Transmits all plant data & status at desired frequency via SMS -

Controls RO/UF/STP Plants

Controls RO/UF/STP Plants -

Transmits status of all auto MPV

Transmits status of all auto MPV -

Allows changing settings & backwash/regeneration remotely with CROWN

Allows changing settings & backwash/regeneration remotely with CROWN

Instrument Monitor (IM)

-

Display 4 instrument values

Display 4 instrument values -

Transmits the above at the desired frequency via SMS

Transmits the above at the desired frequency via SMS -

Transmits status of all auto MPV

Transmits status of all auto MPV -

Allows changing settings & backwash/regeneration remotely with CROWN

Allows changing settings & backwash/regeneration remotely with CROWN

ARO Controller

-

Sequential start/stop based on tank level

Sequential start/stop based on tank level -

LPS & HPS interlock

LPS & HPS interlock -

Auto flushing with RWP & / or HPP

Auto flushing with RWP & / or HPP -

Permeate conductivity indication with alarm

Permeate conductivity indication with alarm -

Sand filter backwash reminder based on RO ON TIME

Sand filter backwash reminder based on RO ON TIME

Dosing Pump

-

Controls with digital display and keys

Controls with digital display and keys -

Automatic batching

Automatic batching -

Automatic air release

Automatic air release -

Highly polished zirconia balls offer excellent NRV characteristics

Highly polished zirconia balls offer excellent NRV characteristics -

Braided 20 kg/cm2 class tubing to prevent pinching

Braided 20 kg/cm2 class tubing to prevent pinching -

4×7 segment LED display

4×7 segment LED display -

110-250 V power supply

110-250 V power supply -

PC enclosure, noryl head, Viton rubber parts and Teflon diaphragm

PC enclosure, noryl head, Viton rubber parts and Teflon diaphragm